The main advantage of polyester enameled aluminum wire is that it is able to withstand high temperatures without losing its structural integrity. In addition, it is corrosion resistant and has a long lifespan. Moreover, it can be coiled into self-supporting coils that eliminate the need for a bobbin, making it easy to use in tight spaces. It also comes in a variety of sizes to suit different applications.

Unlike copper wire, which is sized using a gauge system that refers to its diameter, steel wire is measured in terms of its weight. This method of measuring is called a tensile test and allows manufacturers to accurately predict the amount of current that can be safely passed through a specific wire strand. This information is useful for determining whether a particular size of wire will fit the application at hand.

There are several ways to determine the gauge of a wire, but the most accurate way is to compare it against other wires of the same type and gauge. Many hardware stores carry a variety of wire strands in various sizes, so it is easy to find a match. You can also use a wire gauge tool, which will display the gauge on a screen.

This method of identifying the gauge of a wire can be difficult if the wire is not stamped with a gauge number. If you don't have a wire gauge tool, you can try holding the wire strand next to other wires whose gauge you know. Alternatively, you can also take the wire strand to a hardware store and ask them to compare it against their stock of wires.

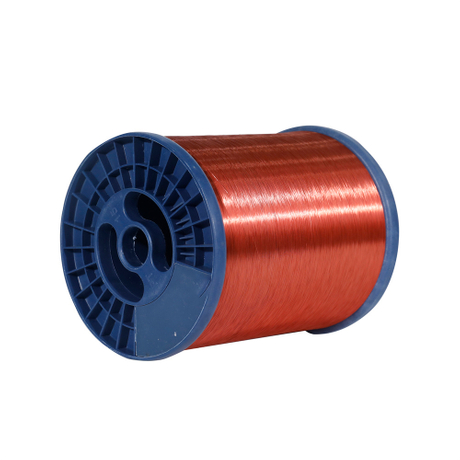

Polyester-imide/polyamide composite enameled wire has a thermal class of 180 and is suitable for oil-immersed or dry-type power transformer windings. It has good mechanical strength, elasticity and adhesion. It also has a high softening breakdown temperature and excellent resistance to moisture and solvents. However, it can be hydrolyzed under closed conditions. In order to prevent this, it is recommended to use protective coatings and to use the right temperature when soldering. The product is widely used in instruments, electric appliances and telecommunication equipment. It can be supplied in whole bobbins or in a smaller quantity, depending on the customer's requirement. It can also be provided in a light yellow carton box to protect the wire during transport. Each bobbin is marked with the nominal net weight, enamel type and other relevant information.