Enamelled copper round wire, a staple in the electrical industry, represents a perfect synergy of form and function. This meticulously crafted wire serves a multitude of applications, from transformers and motors to inductors and coils, embodying the precision and reliability demanded by modern electrical engineering. Let's explore the unique characteristics and versatile applications that make enamelled copper round wire an indispensable component in the world of electrical systems.

The foundation of enamelled copper round wire lies in its construction. The core material, copper, is chosen for its exceptional electrical conductivity, ensuring efficient transmission of electrical signals. The copper wire is meticulously coated with a thin layer of enamel insulation, which not only provides electrical insulation but also protects the wire from external factors such as moisture, chemicals, and temperature variations.

One of the primary advantages of enamelled copper round wire is its compact design. The thin enamel insulation allows for a more streamlined and space-efficient wire, making it ideal for applications where size constraints are a critical consideration. This compact design contributes to the efficiency of electrical devices, enabling the creation of smaller, lighter, and more energy-efficient components.

Thermal resistance is a key feature of enamelled copper round wire. The enamel insulation is carefully selected and applied to withstand elevated temperatures, making this type of wire well-suited for applications where heat is a factor. This thermal resilience ensures the stability and longevity of the wire, even in environments with demanding temperature conditions.

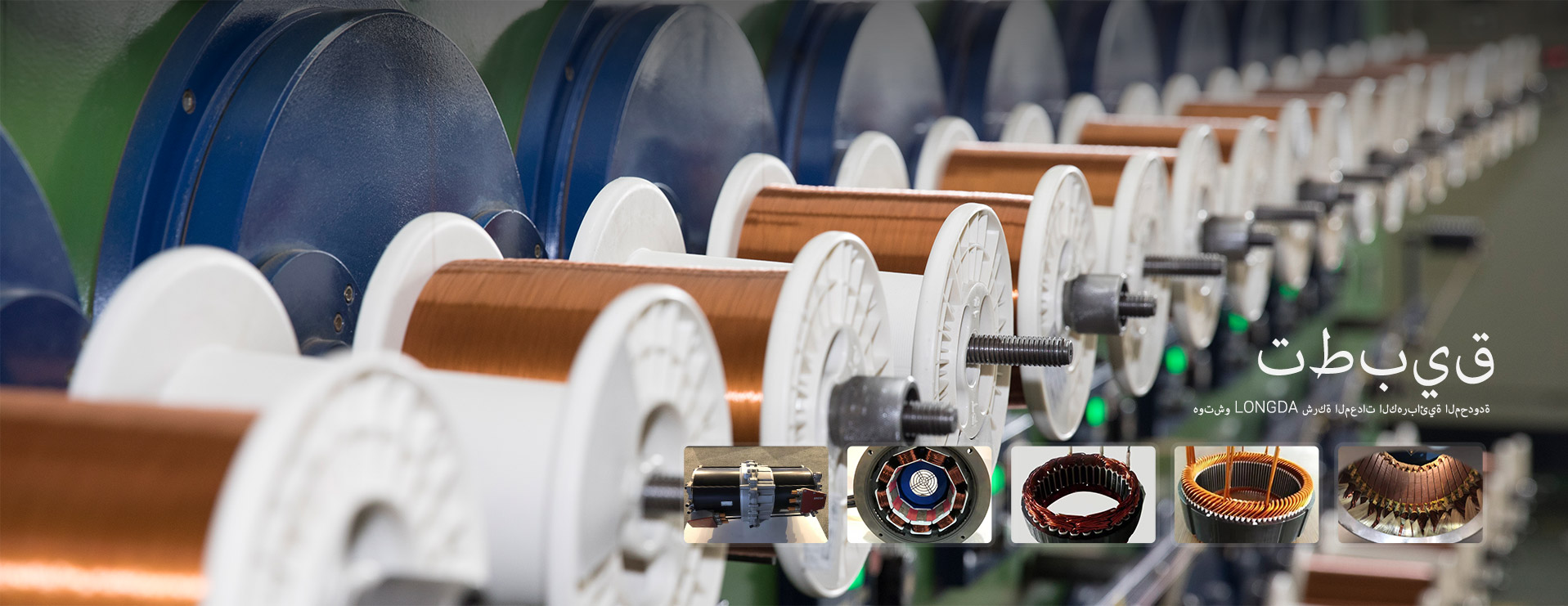

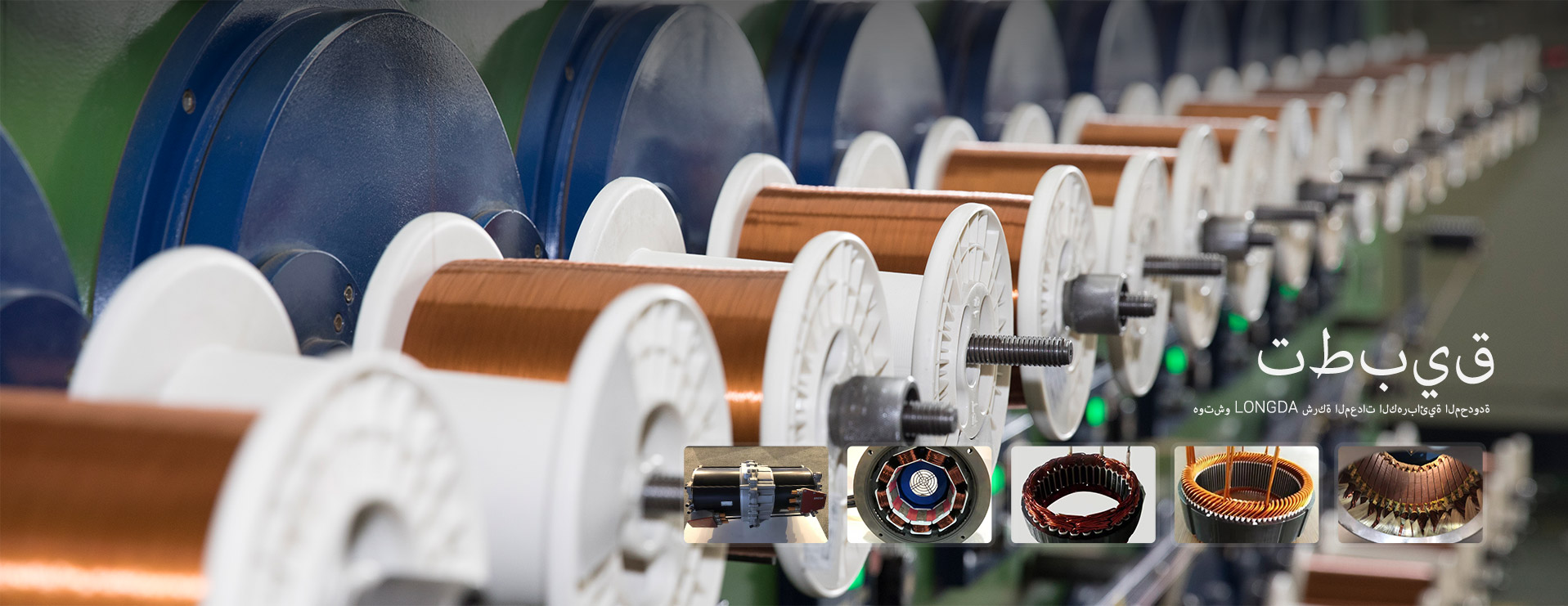

The versatility of enamelled copper round wire extends to its use in intricate winding applications. The smooth and uniform enamel coating allows for precise and consistent winding, facilitating the creation of coils and transformers with optimal performance. This precision is crucial in the design and manufacturing of electrical components where reliability and accuracy are paramount.

Enamelled copper round wire is widely utilized in the manufacturing of transformers. The wire's ability to carry alternating currents efficiently, coupled with its thermal resilience, makes it an ideal choice for transformer windings. The enamel insulation provides electrical insulation between winding layers, preventing short circuits and ensuring the transformer's overall reliability.

Motor winding is another prominent application of enamelled copper round wire. The wire's high conductivity and thermal resistance make it suitable for use in electric motors, where efficient energy transfer and heat dissipation are critical. The enamel insulation acts as a protective barrier, safeguarding the wire against potential damage and maintaining the motor's performance over its operational life.