What are the main uses of electromagnetic wires?

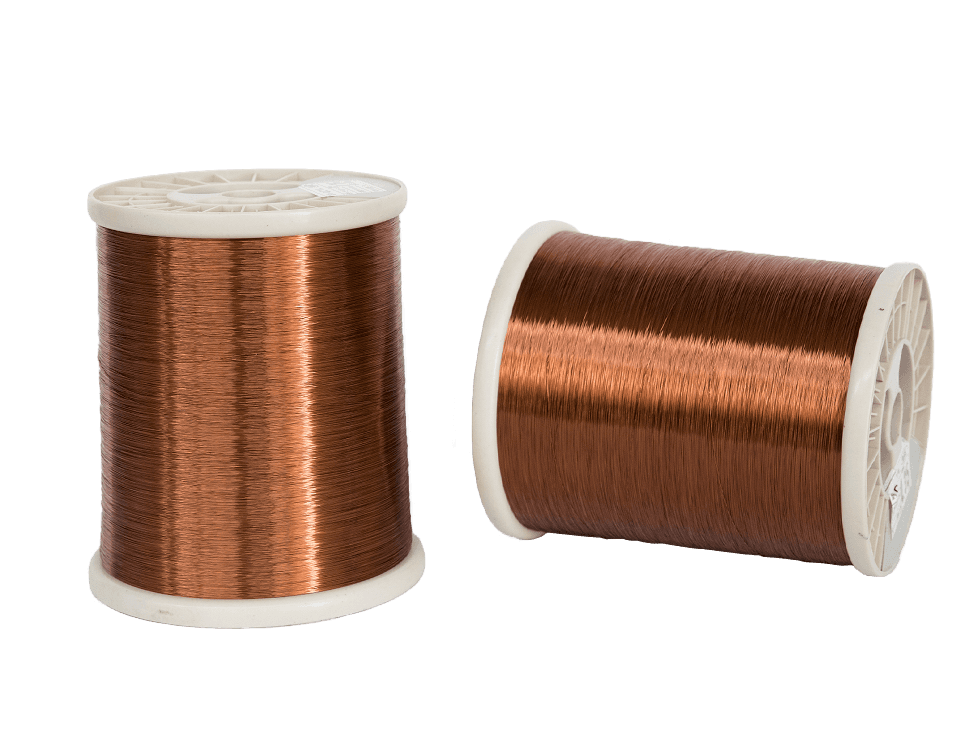

Electromagnetic wire is a certain number of enamelled copper flat wires combined into two rows with wide surfaces in contact with each other, and the same direction is changed along the narrow surface above and below the two rows of enameled flat wires as required, and then used Insulation paper and rope or tape are used as continuous winding wires.

At present, the electromagnetic wire is mainly used to manufacture various types of power transformers, and traction transformers and reactor windings.

Generally, the winding method of the electromagnetic wire mainly includes all overlapping windings and all gap windings; usually the inner and outer two layers overlap the wrapping, and the remaining layers wrap the wrapping.

Motor enameled wire is an important market output of electromagnetic wire. Generally, this type of electromagnetic wire is composed of a conductor and an insulating layer. After several times of bare wire annealing and softening, it is made by baking and painting for many times. Depending on the application field used, the manufacturing process is also different.

It is not easy to produce a motor enamelled copper wire product that meets the requirements of the standard and meets the requirements of customers. It is affected by factors such as raw material quality, process parameters, and production equipment environment.

Therefore, the quality characteristics of the enamelled copper wire of the motor are different from the enameled copper wire, but they all have four major properties: mechanical properties, chemical properties, electrical properties, and thermal properties.

Generally, the motor enamelled copper wire has excellent high temperature resistance, mechanical properties, electrical and chemical properties, and excellent freezing resistance. It is suitable for refrigeration equipment, dry-type transformers, oil-immersed transformers, iron separators, and electromagnetics that work for a long time at 200 ℃ Iron and other mechanical and electrical equipment.

Motor enamelled copper wire is not only used for equipment but also the main raw material commonly used by aluminum artists. And the motor enamelled copper wire was originally used in crafts. And its special color and physical nature determine the noble and elegant crafts.

The enameled wire and electromagnetic wire mainly use insulating electrostatic powder coatings. At present, they are mainly applied to the insulating oxide film electromagnetic wire that replaces the metal aluminum wire with concentrated sulfuric acid treatment, and can also be applied to the enameled wire coated with insulating paint.

Since the thickness of a general powder coating is suitable for a round wire with a diameter of 1.6 mm or more or a rectangular wire with a width × thickness of 1.6 mm × 1.6 mm or more, and an insulating coating with a thickness of 40 μm or more, so It is not applicable when a thin coating film is required. If the ultra-thin powder coating can be used, it can achieve a thickness of 20 to 40 μm, but because of the high processing cost and difficulty of coating, it has not been widely applied. When the thickness of the coating film is too thick, the flexibility and other functions of the coating film are reduced, and it is not suitable for products with too large a bending angle of the metal wire. Due to the limitation of the thickness of the coating film, too thin metal wires are not suitable for the application of powder coating technology.

English

English 简体中文

简体中文 España

España Russian

Russian العربية

العربية