- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 169 Author: Site Editor Publish Time: 2025-10-03 Origin: Site

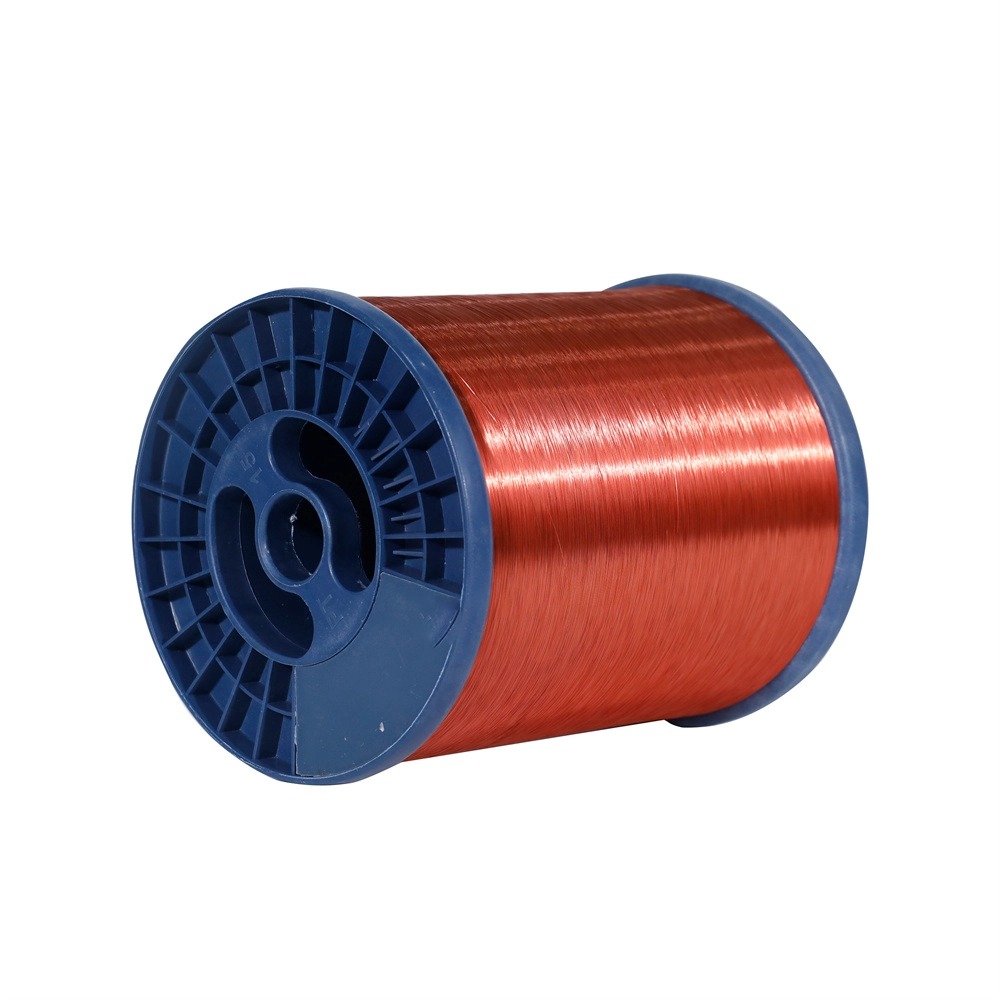

Polyurethane Enameled Copper Wire is a game-changer in electrical systems. Why do industries prefer it over other materials? This article explores its benefits and importance in electrical applications. You'll learn how it enhances conductivity, durability, and efficiency across various sectors.

Polyurethane enameled copper wire stands out in electrical applications for several key reasons. Its superior conductivity and stability make it a preferred choice where reliable current flow is critical. Copper naturally has excellent electrical conductivity, second only to silver, which means it can carry more current efficiently than many other metals. This quality ensures minimal energy loss during transmission, boosting overall system performance.

Beyond conductivity, polyurethane enamel adds a protective layer that enhances the copper wire's durability. This coating resists oxidation and corrosion, common problems that degrade wire performance over time. By preventing these issues, the wire maintains stable electrical properties and a longer service life, even in harsh environments. This resistance also reduces maintenance needs and improves safety, as oxidized wires can cause faults or failures.

Applications of polyurethane enameled copper wire are widespread, especially in power transmission and motor windings. In power systems, it enables efficient energy transfer, reducing heat generation and energy waste. In motor windings, the wire’s stability and conductivity support smooth motor operation and higher efficiency. These qualities make it ideal for transformers, generators, and various electrical devices that demand consistent performance.

Key benefits include:

Superior Conductivity: Copper’s high conductivity means smaller wire sizes can carry the same current, saving space and material costs.

Thermal and Mechanical Stability: The wire withstands heat and mechanical stress, maintaining performance under demanding conditions.

Oxidation and Corrosion Resistance: Polyurethane enamel protects the wire, extending its lifespan and reliability.

Wide Application Range: From industrial motors to household appliances, the wire suits diverse electrical and electronic uses.

In summary, polyurethane enameled copper wire combines copper’s natural electrical advantages with a durable coating, making it a reliable and efficient choice for many electrical applications.

Polyurethane enameled aluminum wire offers unique benefits that make it a strong contender in specific electrical applications. Its standout feature is its lightweight nature. Aluminum weighs about one-third as much as copper, making it ideal where reducing weight is critical. This advantage helps lower transportation costs and eases installation, especially in industries where every gram counts.

Cost-effectiveness is another major benefit. Aluminum is generally more affordable than copper, which can significantly reduce production expenses. For manufacturers aiming to balance performance and budget, aluminum wire coated with polyurethane enamel presents a practical solution. The protective polyurethane layer also enhances the wire’s durability by providing good insulation and resistance to environmental factors.

In terms of electrical performance, polyurethane enameled aluminum wire performs well in low-frequency current transmission. While its conductivity is lower than copper’s, it functions efficiently in applications where high-frequency currents are not dominant. This makes it suitable for devices and systems operating within these parameters without sacrificing reliability.

Industries such as aerospace and automotive benefit greatly from this wire type. Aerospace equipment demands materials that combine light weight and reliable conductivity to optimize fuel efficiency and performance. Similarly, automotive manufacturers use enameled aluminum wire in electric vehicle drive motors and other components to reduce overall vehicle weight, enhancing battery range and efficiency.

Key advantages include:

Lightweight: About one-third the weight of copper, reducing transport and installation challenges.

Cost-Effective: Lower raw material costs help manufacturers save on production.

Good Performance in Low-Frequency Applications: Reliable for many common electrical uses.

Ideal for Aerospace and Automotive: Meets strict weight and cost requirements without compromising quality.

Overall, polyurethane enameled aluminum wire suits applications where weight and cost are priorities, and electrical demands are moderate. Its protective coating ensures longevity and stable performance in demanding environments.

When choosing between polyurethane enameled copper and aluminum wire, understanding their differences helps pick the right material for each job.

Copper wire excels in electrical conductivity. It carries current more efficiently, meaning less energy loss and better performance. Copper also handles heat well. It resists thermal expansion and maintains stable connections, reducing risks of loosening or failure over time.

Aluminum wire has about 61% of copper’s conductivity. To carry the same current, aluminum wires must be thicker. Aluminum forms an oxide layer naturally, which can reduce conductivity if not properly treated. However, its thermal expansion is higher, so connections need special care to prevent loosening.

Aluminum wire is lighter — about one-third the weight of copper. This makes handling, installation, and transportation easier and cheaper. It’s a big advantage in aerospace, automotive, and large-scale power transmission where every gram counts.

Cost-wise, aluminum is generally less expensive than copper. But because aluminum wires need larger diameters for equal current, the cost savings might balance out depending on the project. Still, for budget-conscious applications, aluminum offers a strong economic benefit.

Copper wire costs more upfront but can save money long-term due to smaller wire sizes and better durability. Its resistance to corrosion and thermal stress means fewer replacements and repairs.

Copper wire suits applications demanding high reliability and efficiency. Residential wiring, communication devices, motor windings, and transformers benefit from copper’s superior conductivity and stability.

Aluminum wire fits well in weight-sensitive or cost-sensitive environments. Overhead power lines, electric vehicle motors, aerospace equipment, and large industrial systems often use aluminum. It’s ideal where weight reduction and budget are priorities without sacrificing basic performance.

| Feature | Copper Wire | Aluminum Wire |

|---|---|---|

| Electrical Conductivity | High (best after silver) | About 61% of copper |

| Thermal Stability | Excellent | Moderate; needs special connectors |

| Weight | Heavier | Lightweight (1/3 of copper) |

| Cost | Higher upfront | Lower upfront |

| Typical Applications | Residential wiring, motors, transformers | Overhead lines, aerospace, EV motors |

Copper wire offers unmatched conductivity and thermal stability, making it the go-to for high-performance, long-lasting applications. Aluminum wire shines where weight and cost matter most, serving well in specialized fields like aerospace and electric vehicles.

Polyurethane enameled copper wire plays a vital role across many industries due to its excellent electrical and mechanical properties. It’s especially prized in motor manufacturing and transformer efficiency, where reliable performance is a must.

In motor manufacturing, these wires form the windings that convert electrical energy into mechanical motion. Copper’s superior conductivity ensures minimal energy loss, which means motors run cooler and more efficiently. The polyurethane enamel coating provides excellent insulation and protects the wire from wear and corrosion, extending the motor’s lifespan.

Transformers also benefit greatly. The high conductivity reduces energy loss during voltage conversion, improving overall efficiency. The thermal stability of copper wire helps transformers handle heat generated during operation without degrading. This stability keeps transformers reliable over long periods, reducing maintenance costs.

Polyurethane enameled copper wire is common in household appliances like refrigerators, washing machines, and air conditioners. These appliances require durable wiring that can withstand frequent use and temperature changes. The wire’s resistance to oxidation and corrosion ensures safety and longevity in these everyday devices.

Communication devices also rely on this wire type. It supports stable signal transmission in phones, computers, and networking equipment. The fine wire gauge possible due to copper’s conductivity allows compact designs, which is essential for modern electronics.

The automotive industry increasingly uses polyurethane enameled copper wire in electronic control units, sensors, and electric vehicle (EV) motors. Its reliability under thermal and mechanical stress suits the demanding automotive environment. In EVs, efficient motor windings help maximize battery life and vehicle range.

Emerging technologies like renewable energy systems and smart devices also benefit. Copper wire’s stable performance ensures these innovations function safely and efficiently, supporting industry growth and technological advancement.

Polyurethane enameled aluminum wire finds its niche in applications where weight savings, cost efficiency, and moderate electrical performance are key. Its unique properties make it a popular choice in several advanced industries.

Electric vehicles (EVs) benefit greatly from the lightweight nature of aluminum wire. Reducing motor weight improves overall vehicle efficiency and extends battery range. Polyurethane enameled aluminum wire serves as the winding material in EV drive motors, where it balances cost and performance. Though aluminum’s conductivity is lower than copper’s, its weight advantage helps manufacturers design lighter, more efficient motors that meet the demands of modern EVs.

Aerospace applications demand materials that combine durability, light weight, and reliable electrical performance. Polyurethane enameled aluminum wire fits this bill well. Its reduced weight contributes to lower aircraft mass, improving fuel efficiency and payload capacity. The polyurethane coating protects the aluminum wire against oxidation and environmental factors common in aerospace environments, ensuring long-term reliability in power systems and control circuits.

Many industries require cost-effective solutions without sacrificing too much on performance. Polyurethane enameled aluminum wire is ideal in such contexts. It is widely used in low-frequency current transmission systems where high conductivity isn’t critical but weight and budget constraints are. Examples include certain consumer electronics, lighting fixtures, and industrial equipment where aluminum wire keeps costs down and simplifies installation due to its lighter weight.

Polyurethane enameled copper and aluminum wires offer distinct advantages and applications. Copper provides superior conductivity and stability, ideal for motors and transformers, while aluminum's lightweight nature benefits aerospace and automotive industries. Choosing the right material depends on specific needs like conductivity or weight considerations. The future potential of these materials is promising, with advancements in durability and eco-friendliness driving industry growth. At Fuda Electric Innovation, these wires are crafted to deliver exceptional performance, meeting diverse electrical demands efficiently.

A: Polyurethane Enameled Copper Wire is used in applications like motor windings, transformers, and household appliances due to its superior conductivity and durability.

A: Polyurethane Enameled Copper Wire offers higher conductivity and thermal stability, making it ideal for high-performance applications compared to aluminum.

A: The polyurethane enamel coating on copper wire provides a protective barrier, preventing oxidation and corrosion, thereby extending the wire's lifespan.

A: Benefits include superior conductivity, thermal and mechanical stability, oxidation resistance, and suitability for diverse applications.